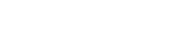

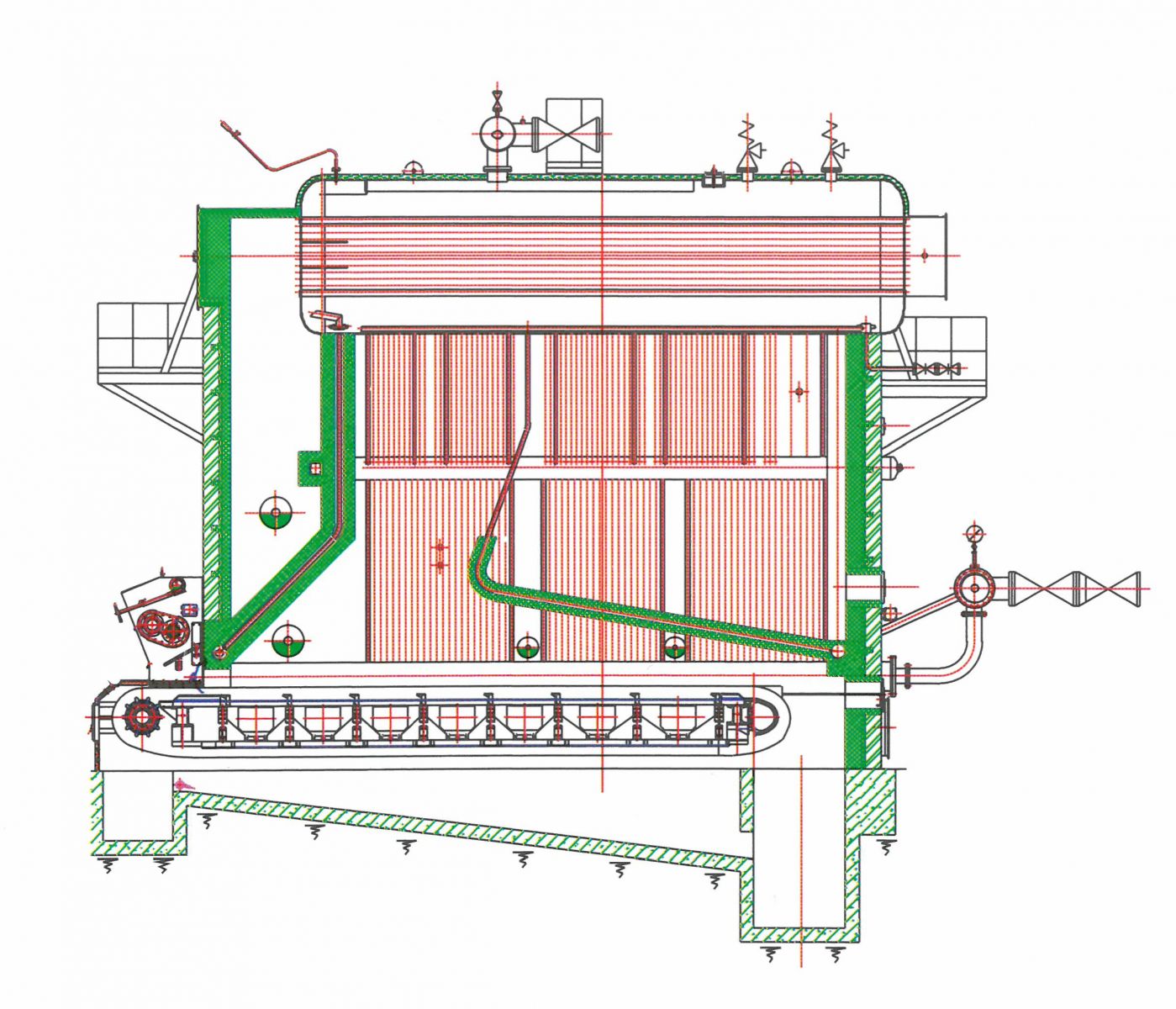

Introduction of TP-DZL New Type Water Tube Boiler:

TP-DZL new type water tube boiler is integrating all advantages of other water and fire boilers in home and abroad.

It is a new generation product and technological achievements of domestic colleges and professional pressure vessel research institutes. It features high technology content when comparing with current industrial boiler it has better burning and heat conducting efficiency. Water cycling is safer and more reliable and with enough output force. The output force and efficiency will not change in the boiler’s lifetime. This boiler is environmental friendly and it can conserve a lot of energy and has great economic and social benefits.

Series TP-DZL New Type Water tube Boiler has the following eight advantages

1) Constant Force:

High efficiency heat conductive screw thread tube is used and the height of screw thread is guaranteed, so we are able to create 10~15% more force than other boilers. The speed of fume is rational so the tubes are free of accumulated dust. The force of boiler and the heat efficiency will not reduce even we extend the operation time. It has an ideal constant force and efficiency.

2) The boiler outer size is largely reduced to save customer’s investment:

High efficiency heat conductive screw thread tubes is used various capacity of hot water boiler with the output water temperature less than l50°C can save on tail heating surface, and the length of boiler can be reduced greatly.

The height of boiler is rather short compare with other boiler type with same capacity. It has the smallest outside dimension and the investment on boiler room will be reduced at least 1/3.

3) No need for special protection for power failure:

Due to mixed cycling is adopted for hot water type and the large volume of boiler, when the power fails there is no need to take special protection measures. Therefore damage of heating surface and media caused by vaporization can be prevented

4) High efficiency:

The main convection heating surface, the screw thread tubes is equipped in shell, so cool wind will not come into the side of the tubes. In addition the removal of tail heating surface will reduce the quantity of cool air along with less heat dissipation. As hot water type adopts mixed cycling, and economizer is not used the water resistance of boiler body is reduced, which is no more than 0.05MPa, the energy consumption of boiler also reduced largely.

The dropping value is obviously larger than the increasing value of fume resistance because of application of screw thread duct. The tail of boiler is set with casting air preheated, which not only increase the adaptability of different type of coal and will help with complete burning of coal, and also reduce the discharging temperature, the operation efficiency of boiler is rated 84%.

5) Quick temperature rising:

The total weight of boiler steel material, heat resistance and insulating materials are less than that other boilers, and high efficiency heat conductive screw thread tubes is equipped in shell, so the time required by temperature rising is greatly shortened, is 1/3 less comparing with other boilers.

6) Safe and reliable:

Adopting protruding panel plate structure with screw thread tube, the thermal pressure of tubes and panel plate is greatly reduced. Lower tank backwater spraying, brushing front edge of side wall, with high temperature plate these will help with prevention on water cooling wall cracking or high temperature plate breaking when used under normal conditions

7) The initial dust discharge is low:

Boiler rear part of hearth is set with dust separation steering chamber; and the volume of hearth is large, so the initial dust discharge of boiler is lower than the allowed value of standard.

8) Easy installation:

Installation duration and installation costs are 1/2 when comparing with other single drum water boiler. It can be put into operation at the same year of manufacturing.

.png)